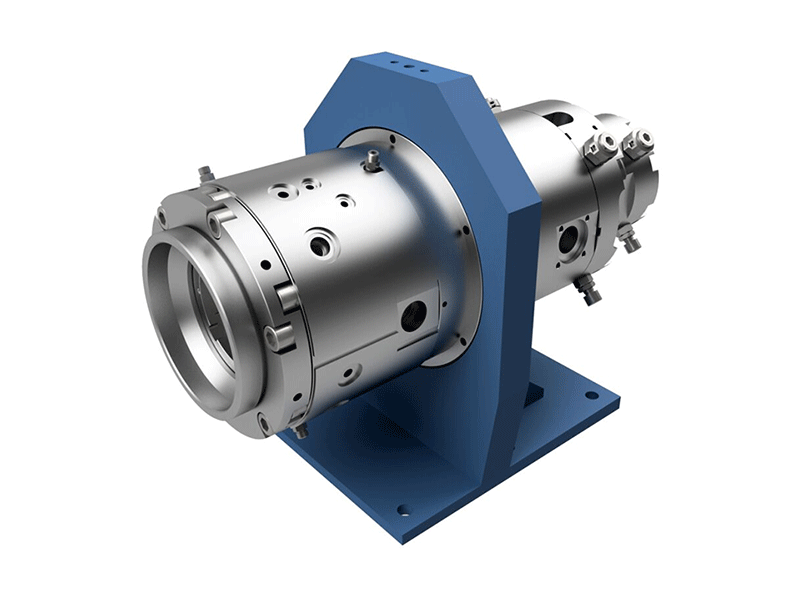

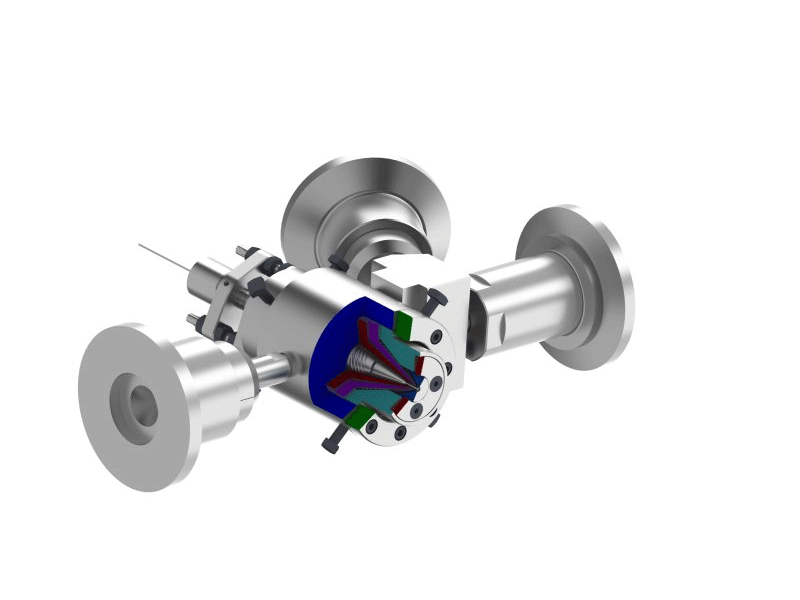

CV Crosshead

A CV Crosshead, also known as a Co-extrusion Crosshead, is an advanced extrusion tool designed specifically for producing co-extruded profiles consisting of multiple materials. Integrated into an extrusion line, this technology allows manufacturers to combine different polymers in a single process, creating products with enhanced properties suitable for various applications.