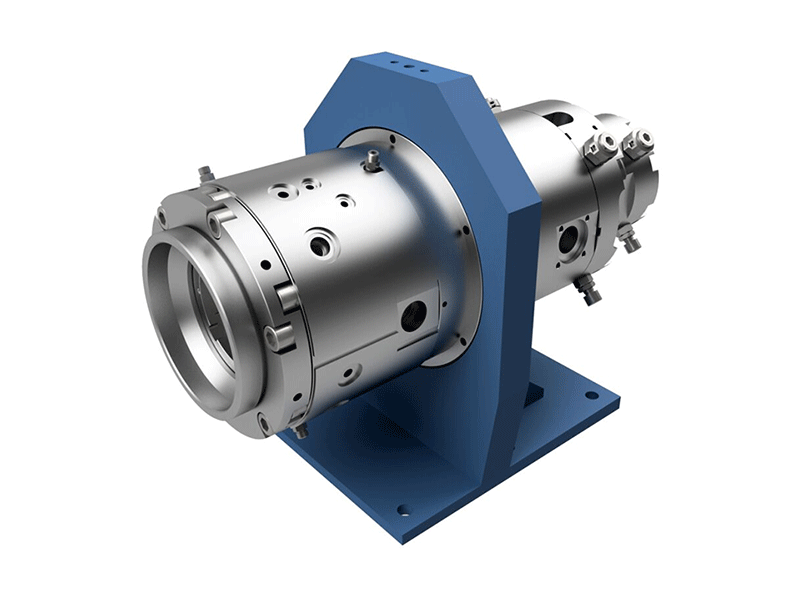

High Quality Crosshead Manufacturers in India

As one of the leading crosshead manufacturers in India, Shree Rang Tech designs crossheads with unmatched precision and user-friendly operation. Engineered with advanced tolerance control, our crossheads consistently deliver tight product specifications, minimizing variations and defects while ensuring accuracy and ease of use.

This superior level of control enhances operational efficiency by reducing downtime and maximizing throughput. Built with a robust design, our crossheads improve the overall quality of the final product, ensuring long-term reliability and reducing rework. Whether for high-demand manufacturing environments or specialized production processes, Shree Rang Tech crossheads are crafted to meet and exceed industry standards—offering dependable solutions that drive performance, consistency, and quality.